Komatsu D155a-6 Bulldozer Service Repair Manual

$39.99

Komatsu D155a-6 Specs Bulldozer Service Repair Manual

This profoundly points by point workshop administration fix manual for download contains for all intents and purposes all that you will ever need to fix, keep up, remake, revamp or reestablish Your Komatsu D155A-6 Bulldozer.

Description

Komatsu D155a-6 Specs Bulldozer Service Repair Manual

DOWNLOAD – D155AX-5

This profoundly points by point workshop administration fix manual for download contains for all intents and purposes all that you will ever need to fix, keep up, remake, revamp or reestablish Your Komatsu D155A-6 Bulldozer.

All symptomatic and fix methodology and provides you with access to similar data that proficient specialists and mechanics have. You can view and print out the total fixed methodology with this workshop administration fix manual download – you don’t should be gifted with a PC.

Komatsu service Manufacturing plant fix manuals are indistinguishable manuals from those utilized by the sellers. As they are essentially planned for seller utilize the makers for the most part discharge a base fix manual when another model is presented (either a solitary manual, multi-volume set or separate volumes) and afterward discharge strengthening manuals as the model changes, for instance, a model facelift or presentation of another motor.

Table of contents:

00 Index and foreword

01 Specification

10 Structure, function, and maintenance standard

20 Standard value tables

30 Testing and adjusting

40 Troubleshooting

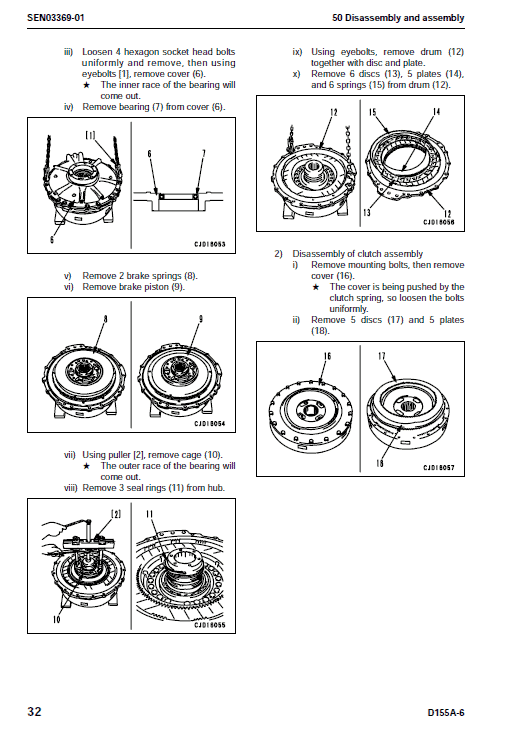

50 Disassembly and assembly

80 Air conditioner

90 Diagrams and drawings

Other Manual

Komatsu D155a-6 Specs Bulldozer Service Repair Manual

Komatsu D155a-6 Specs

Engine and transmission

• Air cleaner, double element with dust

indicator

• Blower cooling fan, hydraulic

• Decelerator pedal

• Engine, Komatsu SAA6D140E-5

• Muffler with rain cap

• Radiator with reserve tank

• TORQFLOW transmission

Electrical system

• Alternator, 24 V/60 A

• Batteries, 2 x 12 V/170 Ah

• Starting motor, 24 V/11 kW

• Working lights (Includes 2 front, 1 rear)

Hydraulic system

• Hydraulics for dozer

• Palm Command Control System (PCCS)

Guard and covers

• Fenders

• Rear cover

• Under guards, oil pan and transmission

Undercarriage

• 560 mm single grouser shoe

• Track roller guard, end sections

• Track shoe assembly

– Sealed and lubricated track

Operator environment

• Large multilingual LCD color monitor

• Rear view mirror

• ROPS/FOPS Cab (ISO 3471/ISO 3449)

• Seat belt

• Suspension seat

Other equipment

• Backup alarm

• Horn, warning