Volvo A25e Articulated Dump Truck Service Repair Manual

CONTENTS AS FOLLOWS:

1. General

2. Service & Maintenance

3.Engine

4.Electrical & Information System

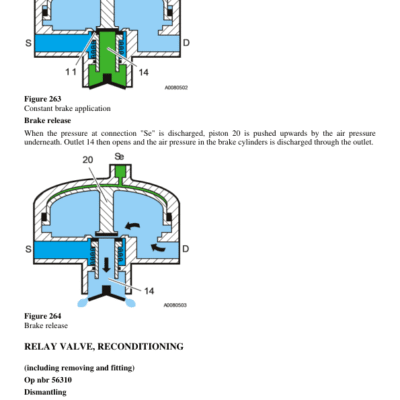

5. Power Transmission

6. Brakes

7. Steering

8. Frame and Track

9. Cab & Interior

10.Hydraulic system, working hydraulics & other equipment

Hydraulics and Electrics shematics.

Product Details:

Volvo A25e Articulated Dump Truck Service Repair Manual

File Format: PDF

Size: 145Mb

Language: English

Specifications: Full Printable

Zoom IN/OUT: YES

Requirements: Adobe PDF Reader & WinZip

Compatible: All Versions of Windows & Mac

The Volvo A25E 4×4 Articulated Dump Truck Service Repair Manual is an essential resource for technicians and operators tasked with maintaining and repairing these heavy-duty vehicles. Here’s what you can expect to find in this comprehensive manual:

- Routine Maintenance Procedures: Detailed instructions for performing routine maintenance tasks, including fluid checks, filter replacements, and lubrication procedures, to ensure optimal performance and longevity of the dump truck.

- Diagnostic Procedures: Step-by-step diagnostic procedures to identify and troubleshoot any malfunctions or performance issues that may arise during operation, helping to minimize downtime.

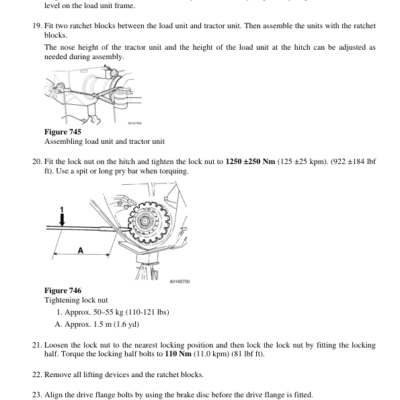

- Repair Instructions: Clear and concise repair instructions for addressing a wide range of issues, from minor adjustments to major component replacements, ensuring efficient and effective repairs.

- Safety Precautions: Essential safety precautions and guidelines to ensure that maintenance and repair tasks are performed safely, reducing the risk of accidents or injuries.

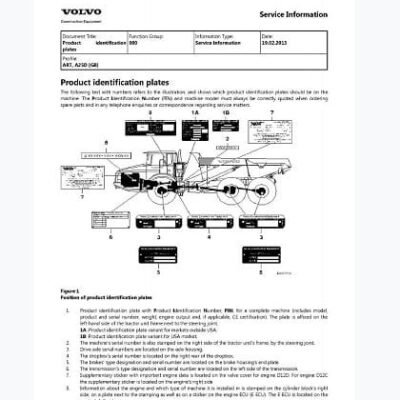

- Component Diagrams and Schematics: Detailed diagrams and schematics of the dump truck’s components and systems to aid in understanding their function and facilitate troubleshooting and repair.

- Parts Catalog: A comprehensive parts catalog with detailed illustrations and part numbers to assist in identifying and ordering replacement parts when needed.

- Special Tools and Equipment: Information on any special tools or equipment required for specific maintenance or repair tasks, ensuring that technicians are properly equipped to perform the work.

- Electrical System: Detailed information on the dump truck’s electrical system, including wiring diagrams and troubleshooting procedures, to address any electrical issues that may arise.

In summary, the Volvo A25E Articulated Dump Truck Service Repair Manual is an invaluable resource for maintaining and repairing these rugged vehicles, helping to ensure their continued reliability and performance in demanding working conditions.

Volvo A25e Articulated Dump Truck Service Repair Manual

Checking brakes: Volvo A25E Articulated Dump Truck

Checking the brakes of the Volvo A25E Articulated Dump Truck is crucial for several reasons:

- Safety: Properly functioning brakes are essential for the safety of both the operator and others on the job site. Regular brake inspections help identify any issues or wear that could compromise braking performance, reducing the risk of accidents and injuries.

- Performance: Efficient brakes ensure optimal stopping power, allowing the dump truck to maneuver safely, especially when navigating steep or uneven terrain. Checking the brakes helps maintain consistent performance and responsiveness, enhancing overall operational efficiency.

- Preventative Maintenance: Routine brake inspections as part of preventative maintenance help catch potential problems early on, before they escalate into more significant issues. Addressing brake-related issues promptly can prevent costly repairs and downtime in the long run.

- Compliance: Ensuring that the brakes meet manufacturer specifications and regulatory standards is essential for compliance with safety regulations and industry standards. Regular brake inspections help maintain compliance with safety regulations and avoid potential fines or penalties.

- Equipment Longevity: Properly maintained brakes contribute to the longevity of the dump truck’s components and systems. By identifying and addressing brake issues early, operators can extend the lifespan of the vehicle and reduce the likelihood of costly repairs or premature component failure.

Volvo A25e Articulated Dump Truck Service Repair Manual