Kobelco Sk140srlc-5 Sk140srl-5 Operator Manual

$29.99

The Kobelco Sk140srlc-5 / SK140SRL-5 Operator Manual is a comprehensive resource designed to help you safely and efficiently operate your Kobelco excavator. Whether you’re a seasoned professional or a newcomer to the field, this manual provides detailed instructions and critical safety information.

Description

Kobelco Sk140srlc-5 Sk140srl-5 Operator Manual

Kobelco Sk140srlc-5 Sk140srl-5 Operator

Kobelco SK140SRLC-5 / SK140SRL-5 Operator Manual: Your Essential Guide

The SK140SRLC-5 / SK140SRL-5 Operator Manual is a comprehensive resource designed to help you safely and efficiently operate your Kobelco excavator. Whether you’re a seasoned professional or a newcomer to the field, this manual provides detailed instructions and critical safety information.

Key features and content: Kobelco Sk140srlc-5

- Detailed machine specifications: Learn about the excavator’s dimensions, weight, engine power, and hydraulic system to understand its capabilities and limitations.

- Step-by-step operation: Follow clear instructions for starting, stopping, and operating the excavator’s various functions, including boom, arm, bucket, and swing.

- Safety guidelines: Prioritize safety with comprehensive guidelines on proper handling, emergency procedures, and preventive maintenance.

- Troubleshooting tips: Find solutions to common problems and learn how to identify and address potential issues.

- Maintenance schedules: Keep your excavator in top condition by following recommended maintenance routines and intervals.

Why you need this manual:

- Safety: Ensure safe operation by following proper procedures and guidelines.

- Efficiency: Maximize productivity by understanding the excavator’s capabilities and limitations.

- Longevity: Extend the life of your machine through proper maintenance and troubleshooting.

- Compliance: Adhere to industry standards and regulations.

Invest in your safety and the performance of your Kobelco excavator. The Operator Manual is an indispensable tool for any owner or operator.

Important Information: Kobelco Sk140srlc-5 Sk140srl-5 Ed160br-5 Service Manual

Preface

Store Operation & Maintenance Manuals On The Machine

Safety Information In Messages Or Labels In This Manual And On The Machine

Safety Labels

Summary Of The Machine

Qualification For Operating The Machine

Fluorinated Greenhouse Gases

“Ec” Declaration Of Conformity

Vibration To The Operator

Noise Level

Cab With Rops (Rollover Protective Structure)/Falling Objects Protective Structure

Ordering Parts And Service

Warranty

Important Notification

Safety Instructions

Safety Labels & Decals

Always Make Sure All Of The Safety Labels Are Legible And Not Damaged

Location Of Safety Labels & Decals

Safety Labels

Prestart Safety

Operation Rules

Protection Tools

Abnormal And Emergency Condition

Potential Hazards When Operating

Fire Prevention

Getting On And Off The Machine

Prestart Up Inspection On The Machine

Secure Visibility

Be Aware Of Your Surroundings

Precautions For Operation

Starting

Traveling

Prohibited Operations

Safety Check On The Parking Machine

At The End Of Each Shift

Precautions Of Inspection & Maintenance

Periodic Inspections

Before Inspection & Maintenance

During Inspection & Maintenance

Prohibited In Inspection & Maintenance

After Inspection & Maintenance

Precautions For Battery

Handling The Battery

Kobelco Sk140srlc-5 Sk140srl-5 Operator Manual

Contents:

Handling Of The Accumulator Or Gas Spring

Towing The Machine

Towing Method Of The Machine

Machine Familiarization

Basic Components Of The Machine

Operator’S Station Nomenclature

Gauge Cluster

Multi display

Engine Coolant Temperature Meter

Fuel Level Meter

Def/Ad blue Level Gauge

Hour Meter

Screen Change Switch

Buzzer Stop Switch

Work Mode Select Switch

Washer Switch

Wiper Switch

Travel Speed Select Switch

Auto Acceleration Switch

Attachment Mode Select Switch

Menu Switch

User Menu Setting

Display For Maintenance

Warning Display Screen

Clogging Detector Of Hydraulic Oil Filter

Handling Of Switches And Meters

Starter Switch

Engine Throttle

Working Light (Boom And Deck)

Working Light Switch (Cab Light)

Manual Regeneration Switch

Pressure Release Switch

Overload Alarm Select Switch

Cab Rotating Light Switch

Quick Hitch Operation Switch

Cap (Option Switch)

Horn Switch

Engine Throttle For Redundant Mode

Swing Parking Brake Release Switch

Kpss Release Switch

Engine Stop Switch

V Power Supply

Usb Port/External Input Terminal (Aux)

Handling Of Levers And Pedals

Location Of Levers And Pedals

Contents

Pilot Control Shutoff Lever

Operator Control Levers

Travel Lever & Pedal

Handling Of Fuse & Relay Box

About Fuse & Relay Box

Replacing Fuses

Fuse Capacity And Circuit Name

Handling Of Fusible Link (For Starter)

Fusible Link Inspection/Replacement

Controller

Dual Monitor

Name Of Each Part

Menu Screen

Main Menu

Picture Adjustment (Picture)

Setting Of Camera Related Items (Camera)

Switching Of Dimmer (Light Adjustment) (Dimmer)

Handling Of Radio

Name Of Each Part

Receivable Frequency

Source On

Switching Source

Fm/Am

Usb Audio

Bluetooth Audio

Aux

Clock Display

Volume Control

Display Change

Menu

Bluetooth Audio Function, And Usb Port/External Input Terminal

Description Of Builtin Wireless Equipment

Air Conditioner

Grille (Air Outlet)

Air Conditioner Control Panel

Air Conditioner Operation Panel

How To Use Air Conditioner

Selfdiagnosis Function In Display Monitor

Handling At Inseason/Offseason

Handling Of Seat Belt

How To Fasten Seat Belt

How To Unfasten Seat Belt

Handling Of Operator’S Seat

Height And Tilt Adjustment

Reclining Adjustment

Front/Rear Seat Adjustment

Arm Rest Adjustment

Kobelco Sk140srlc-5 Sk140srl-5 Operator Manual

Contents

Head Rest Adjustment

Adjusting Air Suspension

Seat Heater (Option)

Lumbar Support

Handling Of Operator’S Seat

Damper Adjustment

Weight Adjustment

Height Adjustment

Reclining Adjustment

Front/Rear Adjustment Of Seat

Tilt Adjustment Of Seat Seating Surface

Front/Rear Adjustment Of Seat Seating Surface

Arm Rest Adjustment

Head Rest Adjustment

Seat Heater

Lumbar Support

Handling Parts Inside Cab

Cab Door Lock

Opening Door From Inside Of Cab

Opening/Closing Front Window (Upper)

Retracting Front Window (Lower)

Cab Room Lamp

Emergency Escape From Operator’S Station

Other Accessories

Tool Box

Grease Gun Holder

Cup Holder

Guard/Side Door (With Lock)

Battery Poweroff Switch

Fuel Supply Pump

Machine Operation

Everyday Checkup

Check Before Starting Engine

Checking Coolant Level And Refilling

Checking Engine Oil Level Of Engine Oil Pan And Refilling

Checking Fuel Level And Refueling

Draining Fuel Prefilter

Checking Oil Level Of Hydraulic Oil Tank

Checking Fan Belt And Air Conditioning Compressor Belt

Checking Radiator, Oil Cooler And Filter

Checking Def/Adblue Level And Refilling

Adjustment Of Operator’S Seat

Adjustment Of Mirrors

Checking Multidisplay

Checking Working Light

Contents

Checking Of Air Cleaner Inlet

Starting Engine

Startup Under Normal Temperature Conditions

Start Up In Cold Conditions

Using Jumper Cables

Stopping Machine Engine

Check After Starting Engine

Check Of Pilot Control Shutoff Lever

Check Of Engine And Multidisplay

Warmingup

Engine Warmingup

Warmingup Hydraulic Oil

Auto Idling Stop Function

Restart After Auto Idle Stop

Selection Of Work Mode

Switching Attachment Mode

Machine Operation

Precautions Of Machine Operation

Travel Procedures

Changing Travel Speed (St And Nd)

Machine Operation In Water Or On Soft Ground

Getting Out Of Soft Ground

Swing And Attachment/Equipment Operations

Work Procedures Of Machine

Digging Work

Loading Work

Always Park Machine Properly

Parking Machine On Slope

Inspection And Check After Operation

Machine Operation In Adverse Conditions

Operation In Cold Condition

Operation At Seashore

Operation In Sandy And Dusty Areas

Precautions For Longterm Storage

Washing Machine

Refilling Oil/Greasing

Battery

Coolant

Prevention Of Dust And Moisture

Periodical Lubricating Operation (During Storage)

Treatment After Longterm Storage

Inspection And Maintenance

General

Inspecting And Maintaing Machine

Periodic Inspection And Maintenance

Contents

Precautions Of Inspection And Maintenance

Exhaust Gas Cleaning Device

About Exhaust Gas Cleaning Device

About Automatic Regeneration

About Manual Regeneration

Inspection And Maintenance

Precautions Of Using Exhaust Gas Cleaning Device

Scr System And Def/Adblue

Scr

Def/Adblue

Def/Adblue Circuit And Battery

Storing Def/Adblue

Purchasing Def/Adblue

Low Def/Adblue Level

Quality Problems Of Def/Adblue

Draining Def/Adblue

Failure Of Exhaust Gas Cleaning Device

Emergency Evacuation Mode

Scr Inspection And Maintenance

Lubricant, Fuel & Coolant Specifications

About Use Of Biooil (Biodegradable Hydraulic Oil)

Grease And Oil For Use

Precautions For Biooil

Replacement Interval Of Biooil

Flushing Procedures Of Biooil

Maintenance Parts

Tightening Torques For Bolts & Nuts (Specific Positions)

Tightening Torques For Bolts & Nuts

Tightening Torques For Joints & Hydraulic Hoses

Inspection And Maintenance Chart

Maintenance When Required

Checking And Replacing Wiper Blades

Washer Fluid Inspection

Replacing Bucket

Replacing Tooth Point And Side Cutter

Inspection And Adjustment Of Bucket Gap Adjustment Mechanism

Bleeding Air From Fuel Piping

Releasing Internal Pressure In Hydraulic System

Hour (Daily) Inspection & Maintenance Procedures

Greasing Attachment

Hour Inspection & Maintenance Procedures

Inspecting And Maintaining Battery

Draining Water And Sediment In Fuel Tank

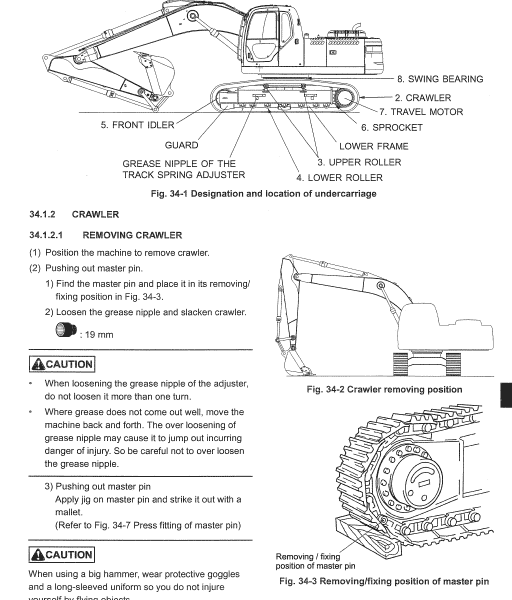

Adjusting Crawler Tension

Hour Inspection & Maintenance Procedures

Checking Engine Oil Level Of Swing Reduction Unit

Checking Oil Level Of Travel Reduction Unit.

Kobelco Sk140srlc-5 Sk140srl-5 Operator Manual

Contents

Hour (Month) Inspection & Maintenance Procedures

Adjusting Fan Belt And Air Conditioning Compressor Belt

Checking Intake System Rubber Hose

Checking Radiator Hoses

Cleaning Or Replacing Air Conditioner Filters

Inspecting, Cleaning, Or Replacing Air Cleaner Element

Cleaning Or Replacing Radiator Cap

Inspecting Scr System

Cleaning Radiator, Oil Cooler Core And Filter

Hour (Month) Inspection & Maintenance Procedures

Replacing Engine Oil And Engine Oil Filter

Replacing Fuel Prefilter

Replacing Fuel Filter

Greasing Swing Bearing

Checking Swing Bearing Mounting Bolt For Looseness

Cleaning Fuel Tank Cap And Strainer

Lubricating Push Rod Of Control Lever

Checking Air Conditioner Refrigerant

Cleaning Or Replacing Electromagnetic Fuel Pump

Hour (Month) Inspection & Maintenance Procedures

Replacing Return Filter

Replacing Air Breather Element

Checking Engine Mounting Bracket For Tightening Condition

Checking Battery Voltage

Hour Inspection & Maintenance Procedures

Replacing Coolant

Replacing Oil In Swing Reduction Unit

Replacing Oil In Travel Reduction Units

Cleaning Suction Strainer

Greasing Swing Reduction Unit

Checking Grease In Swing Grease Bath

Cleaning Pilot Line Filter

Hour Inspection & Maintenance Procedures

Replacing Hydraulic Oil

Replacing Def/Adblue Supply Module Filter

Transportation

Transportation

Strictly Observe Transportation Related Regulations

Loading/Unloading The Machine

Loading

Fixing The Machine

Unloading

Machine Lifting

The Position Of The Lifted Machine

Installing And Removing Mirror

Contents:

Specification

General Specifications

Sksrlc, Sksrl

Shoe Types And Uses

Working Ranges

Backhoe Attachment (Sksrlc)

Backhoe Attachment (Sksrl)

Attachment Type And Combination

Front Attachment Variation

Lifting Capacity

Sksrlc:M (‘”) Boom

Sksrlc:M (‘”) Boom

Sksrl:M (‘”) Boom

Machine Operation Management System

Machine Operation Management System

Remote Download System

Description Of Builtin Wireless Equipment

Optional Equipment

Operation Of Hydraulic Breaker And Nibbler (Crusher)

Do Not Use For Demolition Operation

Selection Of Hydraulic Breaker And Nibbler (Crusher)

Before Operating Hydraulic Breaker

Precautions For Impurity And Hydraulic Oil

Precautions In Use Of Breaker

Precautions In Use Of Nibbler (Crusher)

Selection Of Attachment Mode And Selector Valve

Selection Of Attachment Mode

Switching Selector Valve

Switching Stop Valve

Flow Rate Adjustment

Control Of Proportional Hand Control Extra, Nibbler (Crusher),

Breaker

Extra Hand Control

Horn Switch

Nibbler (Crusher) Operation

Breaker Operation

Control Of Proportional Hand Control Nibbler (Crusher), Breaker

Horn Switch

Nibbler Operation

Breaker Operation

Periodic Inspection And Maintenance Of Nibbler (Crusher) And Breaker

Content: Kobelco Sk140srlc-5

Periodic Inspection And Maintenance Chart Of Nibbler (Crusher) And

Breaker

Reinforcement Of Attachment

Precautions From Breaker Manufacturers

Install High And Low-pressure Accumulators

Accumulator Installation Criteria

Install Relief Valve

Object Handling

Safety Precautions

Lifting Work

Rated Lift Capacity Chart

Quick Hitch

Prohibited Works

Precautions For Use

Removing Front Attachment

Installing Front Attachment

Manual Switching Of Pressure Reducing Valve For Quick Hitch

Travel Alarm Switch

Special Procedures

Special Procedures At Engine Failure

Lowering Attachment To Ground

Releasing Travel Motor Brakes

Releasing Swing Brakes

Swing Brake Release Procedure With Hydraulic Hand Pump

Swing Brake Release Procedure By Disassembly.

Reviews

There are no reviews yet.