Catalog: Heavy Wheel Loader

Make: Komatsu

Model: WA65 WA75 WA80

Sample: komatsu-wa65-wa75-wa80-wheel-loader-workshop-service-manual

Komatsu WA65, WA75, WA80 Wheel Loader Parts Service Manual This handbook is divided into various areas. Each area covers a certain element or system as well as, in addition to the basic solution treatments, consists of disassembling, examining, and assembling instructions. A table of contents is positioned at the start of each section. Pages are easily found by category, as well as each web page is expandable for great information. It remains in the cross-platform PDF file layout so that it works like a beauty on all sort of tools. You do not need to be proficient with a computer to use the handbook.

Store Manual (VEBM250100). pdf.

DESIGN: IDENTIFICATION NUMBER:.

WA65-5 H50051 As Well As UP.

WA70-5 H50051 As Well As UP.

WA80-5 H50051 As Well As UP.

EXCERPT:.

FRAMEWORK As Well As FUNCTION A/c (alternative).

Examining the compressor oil level.

Examine, top up or transform if:.

– Compressor, vaporizer, condenser or drier have to be altered.

– Coolant leakages from coolant circuit.

– Issues accompany the oil in the coolant circuit.

– The ports from compressor or dryer was opened.

Compressor oil adjustment.

Komatsu WA65, WA75, WA80 Wheel Loader Parts Service Manual

1. Get rid of compressor from the car.

2. Drain pipes the oil into a measuring beaker. After the oil has flown out via the line, drain off any type of recurring oil at the drainpipe electrical outlet by turning several times manually.

3. After the oil has actually flown out via the line, drain pipes off any recurring oil at the drainpipe electrical outlet by transforming several times manually.

4. Screw in drainpipe plug with brand-new washer and also tighten. MA = 13 – 15 Nm.

5. Fill up with brand-new compressor oil to exact same quantity as measured amount of drained pipes oil.

Exchange of magnetic clutch.

If the magnetic clutch is faulty:.

– Remove compressor.

– Eliminate old clutch from compressor.

– Link brand-new clutch to compressor.

– Install compressor.

– Activate cooling system.

– Run compressor in neutral.

– Switch over a/c on for 10 secs and also off for 10 secs at least 10 times, check feature of brand-new clutch while doing so.

Exchange of compressor.

– Drain off coolant and dispose it in accordance with guidelines.

– Remount the hoses (1) as well as close them with cabs.

– Loosen up the screws (2) on the compressor.

– Remove the shielding cover as well as belt.

– Remount the compressor.

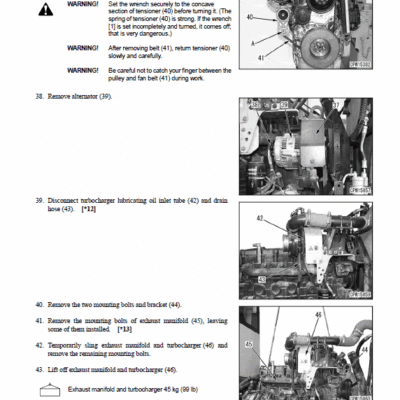

1. Remove the injection pipes and close the connections. Remove the overflow lines. ★ Make sure that no contamination enters the injection pump and injection valves.

2. Remove the injection valve brackets and remove the injection valves.