Komatsu WA470-5H Wheel Loader Workshop Service Repair Manual

This is Komatsu Service Manual the Highly Detailed factory service repair manual for the Komatsu WA470-5H, WA480-5H Wheel Loader, this Service Manual has detailed illustrations as well as step-by-step instructions,It is 100 percents complete and intact. They are specifically written for the do-it-yourself-er as well as the experienced mechanic.

Komatsu WA470-5H Wheel Loader Workshop Service Repair Manual

It is this level of detail, along with hundreds of photos and illustrations, that guide the reader through each service and repair procedure. The complete download comes in PDF format which can work under all PC-based windows operating system and Mac also, All pages are printable. Using this repair manual is an inexpensive way to keep your vehicle working properly.

Models Covers:

WA470-5H Serial WA470H50051 and up

WA480-5H Serial WA480H50051 and up

Service Repair Manual Covers:

Safety

General

Structure and function

Testing and adjusting

Disassembly and assembly

Appendix

And More…

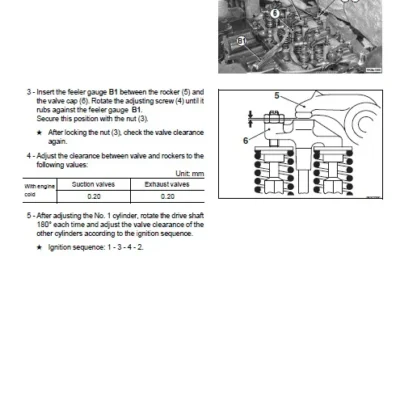

Hydraulic System Maintenance and Component Servicing Guide

1. Hydraulic System Depressurization and Decontamination

Begin by safely relieving system pressure and removing contaminants using appropriate methods, including vacuum pump operation and fluid bleeding procedures.

2. System Diagnostics and Pressure Adjustment

Perform thorough troubleshooting, diagnostic checks, and calibrate hydraulic pressure settings according to manufacturer specifications.

3. Hydraulic Tank Service

Detailed instructions for the removal and reinstallation of the hydraulic fluid reservoir.

4. Pump Maintenance Procedures

Step-by-step guidance for detaching and reinstalling both the main and pilot hydraulic pumps.

5. Hydraulic Control Valve Replacement

Proper techniques for extracting and installing the main control valve unit.

6. Cylinder Service Instructions

Procedures for removing and replacing all attachment actuators.

7. Swivel Joint Servicing

Removal and reinstallation of the hydraulic rotary joint (swivel).

8. Pilot Block Replacement

Instructions for disassembling and reassembling the pilot block assemblies.

9. Swing Drive Motor Handling

Process for removing and reinstalling the hydraulic swing motor.

10. Operator Control Systems

Maintenance of hand levers and foot pedal controls for hydraulic actuation.

11. Solenoid and Safety Valve Servicing

Instructions for managing six-solenoid control valves and the system caution valve.