Sumitomo SH145X-6 Hydraulic Excavator Repair Service Manual

Sumitomo Excavator SH145X-6

Format: PDF

Manual Identification: WLSM1456-00T, WCL145X6-0T, WDL1356-1T

English

Publication: Sumitomo Service Manual

- Sumitomo SH145X-6 Hydraulic Excavator Repair Service Manual – 1358 Pages

- Operators Manual – 272 Pages

- Parts Catalog – 666 Pages

Sumitomo SH145X-6 Manual TABLE OF CONTENTS

Safety………………………………………………………………………………………………………………… 3

Safety, general information and standard torque data…………………………………………… 4

General Information…………………………………………………………………………………………. 5

Standard Torque Data For Cap Screws And Nuts………………………………………………. 14

Specifications And Special Torque Settings………………………………………………………. 15

Abbreviation………………………………………………………………………………………………….. 16

Specifications………………………………………………………………………………………………… 24

Main Equipment Table……………………………………………………………………………………. 33

Overall View………………………………………………………………………………………………….. 51

Main Unit Weight…………………………………………………………………………………………… 57

FLUIDS AND LUBRICANTS……………………………………………………………………………. 75

Circuits and Operation explanation…………………………………………………………………… 79

Main Equipment Structure and Operation Explanation………………………………………… 82

Hydraulic Pump…………………………………………………………………………………………….. 83

Travel Motor………………………………………………………………………………………………… 100

Swing Motor………………………………………………………………………………………………… 113

Control Valve………………………………………………………………………………………………. 121

4 Stack Solenoid Valve Operation Explanation………………………………………………… 160

Upper Pilot Valve (remote control valve)…………………………………………………………. 162

Travel Pilot Valve (remote control valve)…………………………………………………………. 168

Blade Pilot Valve (remote control valve)………………………………………………………….. 173

Cushion Valve …………………………………………………………………………………………….. 175

Engine Summary…………………………………………………………………………………………. 180

Hydraulic Equipment Layout………………………………………………………………………….. 232

Overall View………………………………………………………………………………………………… 233

Port Diagram……………………………………………………………………………………………….. 239

Hydraulic Device………………………………………………………………………………………….. 264

Electrical and Engine Functions and Service Support……………………………………….. 265

Basic Functions…………………………………………………………………………………………… 266

Service Support…………………………………………………………………………………………… 339

Maintenance precautions………………………………………………………………………………. 384

Electrical Equipment Layout Diagram……………………………………………………………… 399

Connection Connector Pin Layout………………………………………………………………….. 429

Sequence Circuit Diagram…………………………………………………………………………….. 432

Safety, general information and standard torque data…………………………………………… 4

General Information…………………………………………………………………………………………. 5

Standard Torque Data For Cap Screws And Nuts………………………………………………. 14

Specifications And Special Torque Settings………………………………………………………. 15

Abbreviation………………………………………………………………………………………………….. 16

Specifications………………………………………………………………………………………………… 24

Main Equipment Table……………………………………………………………………………………. 33

Overall View………………………………………………………………………………………………….. 51

Main Unit Weight…………………………………………………………………………………………… 57

FLUIDS AND LUBRICANTS……………………………………………………………………………. 75

Circuits and Operation explanation…………………………………………………………………… 79

Main Equipment Structure and Operation Explanation………………………………………… 82

Hydraulic Pump…………………………………………………………………………………………….. 83

Travel Motor………………………………………………………………………………………………… 100

Swing Motor………………………………………………………………………………………………… 113

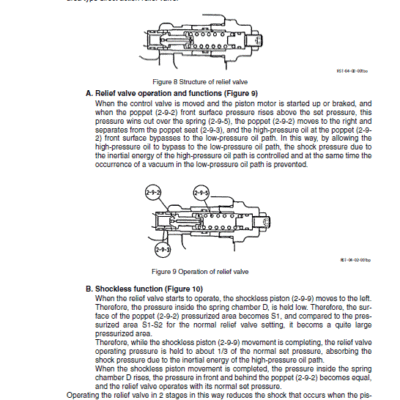

Control Valve………………………………………………………………………………………………. 121

4 Stack Solenoid Valve Operation Explanation………………………………………………… 160

Upper Pilot Valve (remote control valve)…………………………………………………………. 162

Travel Pilot Valve (remote control valve)…………………………………………………………. 168

Blade Pilot Valve (remote control valve)………………………………………………………….. 173

Cushion Valve …………………………………………………………………………………………….. 175

Engine Summary…………………………………………………………………………………………. 180

Hydraulic Equipment Layout………………………………………………………………………….. 232

Overall View………………………………………………………………………………………………… 233

Port Diagram……………………………………………………………………………………………….. 239

Hydraulic Device………………………………………………………………………………………….. 264

Electrical and Engine Functions and Service Support……………………………………….. 265

Basic Functions…………………………………………………………………………………………… 266

Service Support…………………………………………………………………………………………… 339

Maintenance precautions………………………………………………………………………………. 384

Electrical Equipment Layout Diagram……………………………………………………………… 399

Connection Connector Pin Layout………………………………………………………………….. 429

Sequence Circuit Diagram…………………………………………………………………………….. 432

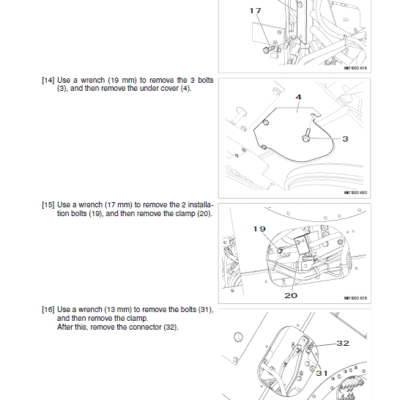

This OEM handbook combines detailed operator instructions with advanced repair procedures from the manufacturer. It includes system diagrams, torque specifications, and parts reference charts, ensuring you have all the data needed for accurate servicing. Learn how to operate, inspect, and maintain your machine according to official standards.

From engine diagnostics to hydraulic calibration, every procedure follows OEM-recommended methods. Mechanics and owners alike will appreciate the clarity of instructions and the comprehensive troubleshooting sections. Investing in this manual means saving time, reducing repair costs, and maintaining your equipment at professional standards.