Sumitomo SH160-5 Hydraulic Excavator Repair Service Manual

Sumitomo Excavator SH160-5

Format: PDF

Manual Identification: WLST1605-00T, WLST1305TS-01W, WLSM1605-00W, WDL1605-1T, WCL1605-0T

English

Jan. 2015

Publication: Sumitomo Service Manual

- Sumitomo SH160-5 Hydraulic Excavator Repair Service Manual – 1816 Pages

- Operators Manual – 228 Pages

- Parts Catalog – 788 Pages

Sumitomo SH160-5 Manual TABLE OF CONTENTS

Safety ……………………………………………………………………………………………………………..1

Introduction……………………………………………………………………………………………………..1

Using Technical Information

Symbols……………………………………………………………………………………………………….1

Precautions for Use

General Preparation for Disassembly ……………………………………………………………..12

General Cautions for Assembly ……………………………………………………………………..14

General Cautions When Performing Inspections………………………………………………18

Tightening Torque

Tightening Bolts and Nuts ………………………………………………………………………………1

Retightening Torque Table………………………………………………………………………………1

Numerical Conversion Table

Engine Section

Procedures for Replacing Consumable Parts

Engine Oil Replacement…………………………………………………………………………………1

Engine Oil Filter Element Replacement…………………………………………………………….4

Fuel Filter Replacement …………………………………………………………………………………5

Charge Fuel Pump Filter Replacement …………………………………………………………..11

Air Conditioner Belt Replacement ………………………………………………………………….13

Fan Belt Replacement ………………………………………………………………………………….16

Assembly and Disassembly

Removal and Installation of Engine Hood………………………………………………………….1

Removal and Installation of Engine Assembly……………………………………………………3

Removal and Installation of Starter Motor ……………………………………………………….14

Removal and Installation of Alternator…………………………………………………………….16

Removal and Installation of Supply Pump ……………………………………………………….18

Removal and Installation of Common Rail……………………………………………………….28

Removal and Installation of Injector………………………………………………………………..31

Removal and Installation of Muffler ………………………………………………………………..41

Removal and Installation of Turbo Charger ……………………………………………………..43

Removal and Installation of EGR Cooler and EGR Valve…………………………………..47

Removal and Installation of Engine Sensors ……………………………………………………49

Removal and Installation of Fuel Cooler………………………………………………………….50

Removal and Installation of Engine Inter Cooler ………………………………………………51

Swing Unit

Removal and Installation of Swing Unit …………………………………………………………….1

Assembly and Disassembly of Swing Unit…………………………………………………………6

Assembly and Disassembly of Swing Motor…………………………………………………….11

Assembly and Disassembly of Swing Reduction Gear………………………………………35

Center Joint

Removal and Installation of Center Joint …………………………………………………………..1

Center Joint Assembly and Disassembly ………………………………………………………….6

Disassembling and Assembling Instructions ……………………………………………………..7

Counterweight

Removal and Installation of Counterweight ……………………………………………………….1

Hydraulic Pump

Removal and Installation of Hydraulic Pump ……………………………………………………..1

Procedures for Assembly and Disassembly of Pump Main Unit Section………………..7

Pump Main Unit Section Maintenance Standards …………………………………………….17

Explanation of Regulator Operation………………………………………………………………..23

Procedures for Assembly and Disassembly of Regulator…………………………………..29

Procedures for Assembly and Disassembly of PTO Unit……………………………………40

PTO Unit Maintenance Standards ………………………………………………………………….46

Remote Control Valve

Removal and Installation of Operation Remote Control Valve………………………………1

Procedures for Assembly and Disassembly of Operation Remote Control Valve…..10

Removal and Installation of Travel Remote Control Valve ………………………………….23

Procedures for Assembly and Disassembly of Travel Remote Control Valve ………..26

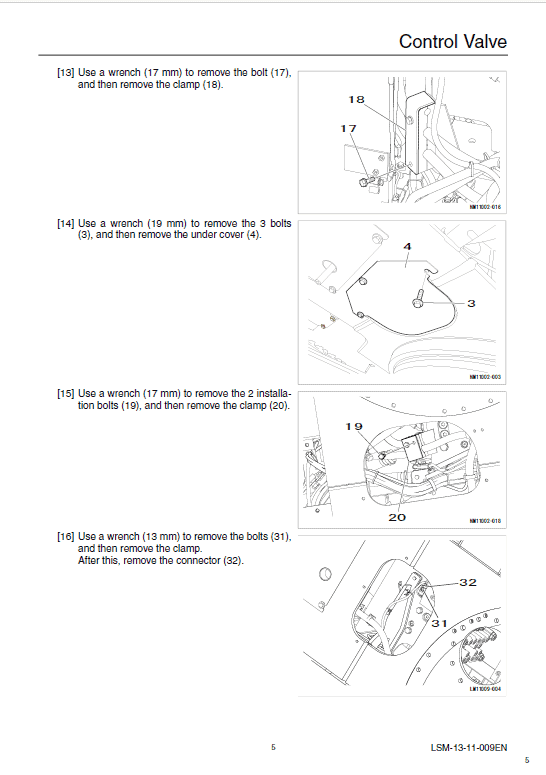

Control Valve

Removal and Installation of Control Valve …………………………………………………………1

Assembly and Disassembly Precautions…………………………………………………………..9

Inspection and Handling ……………………………………………………………………………….10

Replacing the Main Plunger ………………………………………………………………………….12

Accessories ………………………………………………………………………………………………..13

External shape diagram………………………………………………………………………………..14

Cross-section Structure Diagram……………………………………………………………………15

Assembly and Disassembly…………………………………………………………………………..27

Other Valves

Removal and Installation of Solenoid Valve……………………………………………………….1

Removal and Installation of Cushion Valve………………………………………………………..5

Assembly and Disassembly of Cushion Valve……………………………………………………9

Radiator and Oil Cooler

Removal and Installation of Radiator………………………………………………………………..1

Removal and Installation of Oil Cooler ……………………………………………………………..9

Tank

Removal and Installation of Hydraulic Oil Tank…………………………………………………..1

Removal and Installation of Fuel Tank………………………………………………………………7

Attachments

Removal and Installation of Bucket…………………………………………………………………..1

Removal and Installation of Bucket Link……………………………………………………………3

Removal and Installation of Bucket Cylinder ……………………………………………………..6

Removal and Installation of Arm Cylinder………………………………………………………..10

Removal and Installation of Arm…………………………………………………………………….15

Removal and Installation of Boom Cylinder……………………………………………………..17

Removal and Installation of Boom ………………………………………………………………….22

Removal and Installation of Arm HBCV…………………………………………………………..27

Removal and Installation of Boom HBCV………………………………………………………..29

Operation and Assembly/Disassembly of Hydraulic Cylinder ……………………………..32

Structural Diagram……………………………………………………………………………………….61

Introduction……………………………………………………………………………………………………..1

Using Technical Information

Symbols……………………………………………………………………………………………………….1

Precautions for Use

General Preparation for Disassembly ……………………………………………………………..12

General Cautions for Assembly ……………………………………………………………………..14

General Cautions When Performing Inspections………………………………………………18

Tightening Torque

Tightening Bolts and Nuts ………………………………………………………………………………1

Retightening Torque Table………………………………………………………………………………1

Numerical Conversion Table

Engine Section

Procedures for Replacing Consumable Parts

Engine Oil Replacement…………………………………………………………………………………1

Engine Oil Filter Element Replacement…………………………………………………………….4

Fuel Filter Replacement …………………………………………………………………………………5

Charge Fuel Pump Filter Replacement …………………………………………………………..11

Air Conditioner Belt Replacement ………………………………………………………………….13

Fan Belt Replacement ………………………………………………………………………………….16

Assembly and Disassembly

Removal and Installation of Engine Hood………………………………………………………….1

Removal and Installation of Engine Assembly……………………………………………………3

Removal and Installation of Starter Motor ……………………………………………………….14

Removal and Installation of Alternator…………………………………………………………….16

Removal and Installation of Supply Pump ……………………………………………………….18

Removal and Installation of Common Rail……………………………………………………….28

Removal and Installation of Injector………………………………………………………………..31

Removal and Installation of Muffler ………………………………………………………………..41

Removal and Installation of Turbo Charger ……………………………………………………..43

Removal and Installation of EGR Cooler and EGR Valve…………………………………..47

Removal and Installation of Engine Sensors ……………………………………………………49

Removal and Installation of Fuel Cooler………………………………………………………….50

Removal and Installation of Engine Inter Cooler ………………………………………………51

Swing Unit

Removal and Installation of Swing Unit …………………………………………………………….1

Assembly and Disassembly of Swing Unit…………………………………………………………6

Assembly and Disassembly of Swing Motor…………………………………………………….11

Assembly and Disassembly of Swing Reduction Gear………………………………………35

Center Joint

Removal and Installation of Center Joint …………………………………………………………..1

Center Joint Assembly and Disassembly ………………………………………………………….6

Disassembling and Assembling Instructions ……………………………………………………..7

Counterweight

Removal and Installation of Counterweight ……………………………………………………….1

Hydraulic Pump

Removal and Installation of Hydraulic Pump ……………………………………………………..1

Procedures for Assembly and Disassembly of Pump Main Unit Section………………..7

Pump Main Unit Section Maintenance Standards …………………………………………….17

Explanation of Regulator Operation………………………………………………………………..23

Procedures for Assembly and Disassembly of Regulator…………………………………..29

Procedures for Assembly and Disassembly of PTO Unit……………………………………40

PTO Unit Maintenance Standards ………………………………………………………………….46

Remote Control Valve

Removal and Installation of Operation Remote Control Valve………………………………1

Procedures for Assembly and Disassembly of Operation Remote Control Valve…..10

Removal and Installation of Travel Remote Control Valve ………………………………….23

Procedures for Assembly and Disassembly of Travel Remote Control Valve ………..26

Control Valve

Removal and Installation of Control Valve …………………………………………………………1

Assembly and Disassembly Precautions…………………………………………………………..9

Inspection and Handling ……………………………………………………………………………….10

Replacing the Main Plunger ………………………………………………………………………….12

Accessories ………………………………………………………………………………………………..13

External shape diagram………………………………………………………………………………..14

Cross-section Structure Diagram……………………………………………………………………15

Assembly and Disassembly…………………………………………………………………………..27

Other Valves

Removal and Installation of Solenoid Valve……………………………………………………….1

Removal and Installation of Cushion Valve………………………………………………………..5

Assembly and Disassembly of Cushion Valve……………………………………………………9

Radiator and Oil Cooler

Removal and Installation of Radiator………………………………………………………………..1

Removal and Installation of Oil Cooler ……………………………………………………………..9

Tank

Removal and Installation of Hydraulic Oil Tank…………………………………………………..1

Removal and Installation of Fuel Tank………………………………………………………………7

Attachments

Removal and Installation of Bucket…………………………………………………………………..1

Removal and Installation of Bucket Link……………………………………………………………3

Removal and Installation of Bucket Cylinder ……………………………………………………..6

Removal and Installation of Arm Cylinder………………………………………………………..10

Removal and Installation of Arm…………………………………………………………………….15

Removal and Installation of Boom Cylinder……………………………………………………..17

Removal and Installation of Boom ………………………………………………………………….22

Removal and Installation of Arm HBCV…………………………………………………………..27

Removal and Installation of Boom HBCV………………………………………………………..29

Operation and Assembly/Disassembly of Hydraulic Cylinder ……………………………..32

Structural Diagram……………………………………………………………………………………….61

This official workshop manual provides the most accurate technical information available for your machine. Created by the original manufacturer, it covers complete service procedures, mechanical adjustments, and parts identification. Each chapter is organized for easy reference, offering exploded diagrams, torque specifications, and safety guidelines.

Whether you’re troubleshooting hydraulic issues, replacing filters, or overhauling major components, this guide ensures you perform every task correctly. Designed for both professionals and DIY owners, it includes practical maintenance tips that prevent costly breakdowns. Keep your loader, tractor, or excavator running smoothly with this essential workshop companion—your ultimate source for expert-level repair knowledge and manufacturer-approved service procedures.