Bobcat TL38.70X, TL38.70 Telescopic Service Repair Manual

Language English

Format: PDF

All Service Manual includes Wiring and Hydraulic Schematics

Applicable Serial Number:

For Model TL38.70, TL38.70X

S/N AVDV14000 – AVDV14999

S/N AVDV15000 & Above

S/N AVKJ14000 – AVKJ14999

S/N AVKJ15000 & Above

S/N AHT414000 – AHT414999

S/N AHT415000 & Above

S/N AVKM14000 – AVKM14999

S/N AVKM15000 & Above

- Bobcat TL38.70, TL38.70X VersaHANDLER Telescopic Service Repair Manual

- Operation and Maintenance Manual

These service manual contains all the information required to assist you or a trained service engineers with all work, repairs and maintenance on this VersaHANDLER Telescopic.

SERVICE MANUAL CONTENT:

Safety and maintenance . . . 10-01

HYDRAULIC SYSTEM. . . 20-01

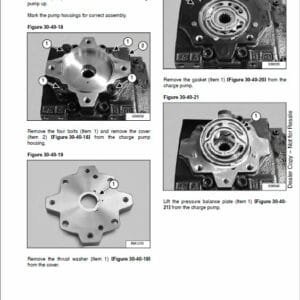

HYDROSTATIC SYSTEM . . . 30-01

DRIVE SYSTEM. . . . 40-01

MAINFRAME. . . . 50-01

Electrical system and analysis. . . 60-01

ENGINE SERVICE . . . 70-01

HEATING, VENTILATION, AIR CONDITIONING (HVAC). . . 80-01

SPECIFICATIONS. . . SPEC-01

ALPHABETICAL INDEX. . . .INDEX-01

Bobcat TL38.70 TL38.70X service manual instructions are necessary before operating or servicing machine. Read and understand the Operation & Maintenance Manual, Operator s Handbook and signs (decals) on the machine. Follow warnings and instructions in the manuals when making repairs, adjustments or servicing. Check for correct function after adjustments, repairs or service. Untrained operators and failure to follow instructions can cause injury or death.

These manual is for the Bobcat TL38.70 TL38.70X VersaHANDLER Telescopic. It provides necessary servicing and adjustment procedures for the Bobcat TL38.70 TL38.70X VersaHANDLER Telescopic and its components and systems. Refer to the Operation & Maintenance Manual and service manual for operating instructions, repair, starting procedure, daily checks, etc.

Bobcat TL38.70X, TL38.70 Telescopic Service Repair Manual

Introduction

The Bobcat TL38.70X and TL38.70 Telescopic Service Repair Manual provides technicians, operators, and service professionals with detailed instructions for maintaining, diagnosing, and repairing these telescopic handlers. Designed to ensure maximum machine performance and reliability, this manual follows official factory standards and is essential for professional service work.

Table of Contents

1. General Information

Safety instructions and precautions

Identification numbers and model details

Technical specifications and capacities

Required tools and workshop equipment

2. Maintenance and Lubrication

Routine service schedules

Lubrication points and recommended fluids

Preventive maintenance procedures

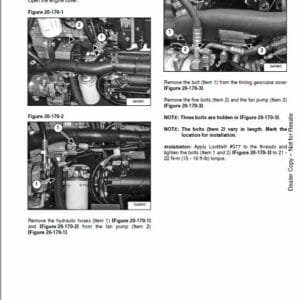

3. Engine System

Engine specifications

Fuel system components

Cooling system service

Exhaust system details

4. Powertrain

Transmission overview

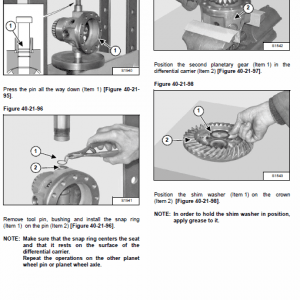

Drive axle and differential

Propeller shaft and final drives

5. Hydraulic System

Hydraulic circuit diagrams

Pump and control valve servicing

Cylinder repair and replacement

Pressure testing and adjustments

6. Electrical System

Wiring diagrams and schematics

Battery, alternator, and starter service

Lighting and instrumentation

Electronic control unit (ECU) functions

7. Steering and Brake System

Steering components and alignment

Hydraulic-assisted steering system

Service brake and parking brake maintenance

Troubleshooting brake issues

8. Cab and Controls

Operator’s cab features

HVAC (heating, ventilation, air conditioning) system

Instrument panel and control levers

Safety switches and monitoring devices

9. Boom and Frame Structure

Telescopic boom inspection and repair

Lifting capacity and safety checks

Frame welding and structural reinforcements

10. Troubleshooting and Diagnostics

Common problems and solutions

Error codes and diagnostic procedures

Testing equipment usage